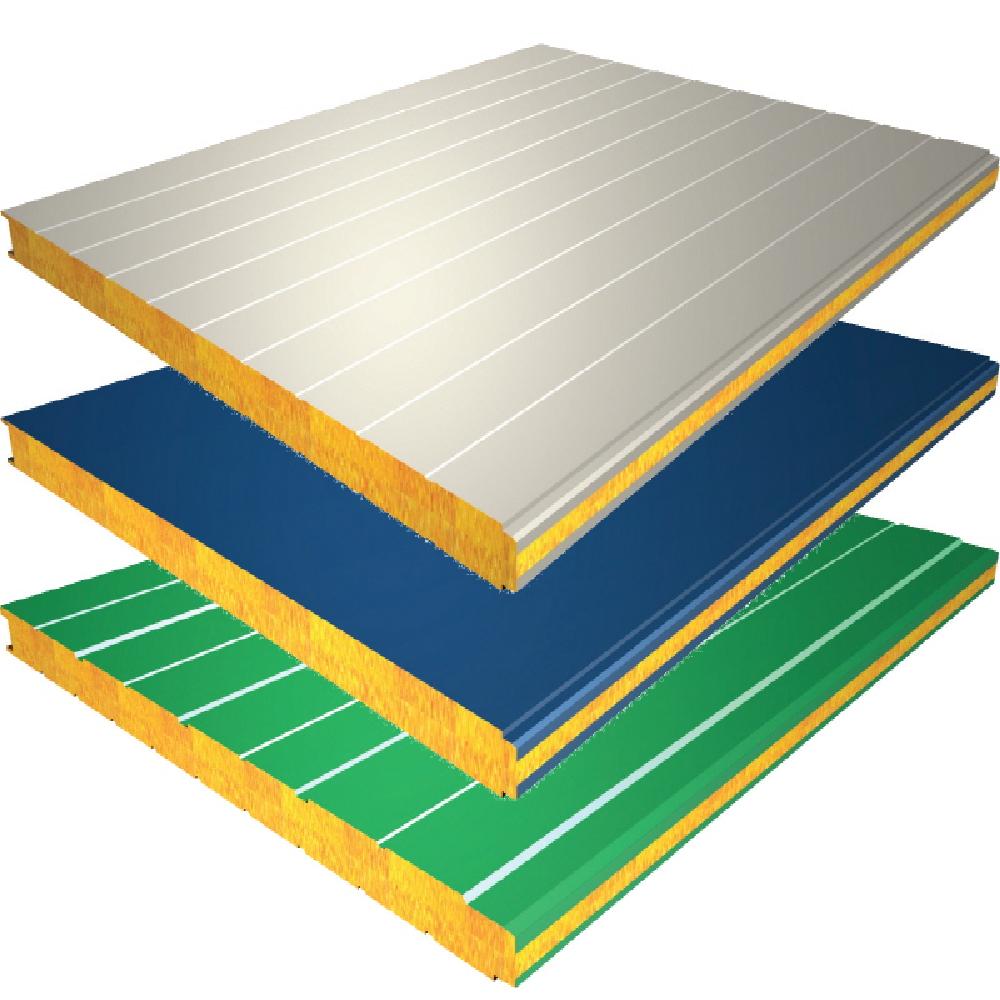

Glass wool Panel

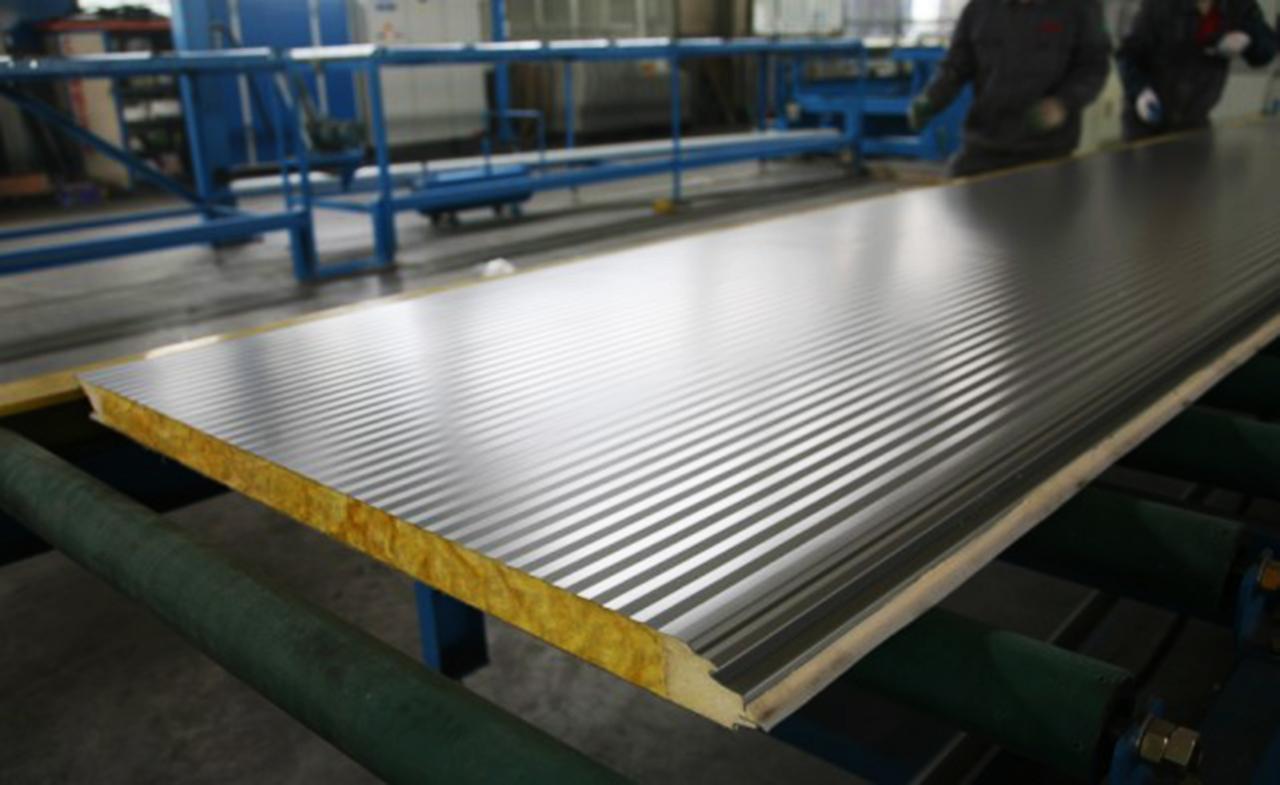

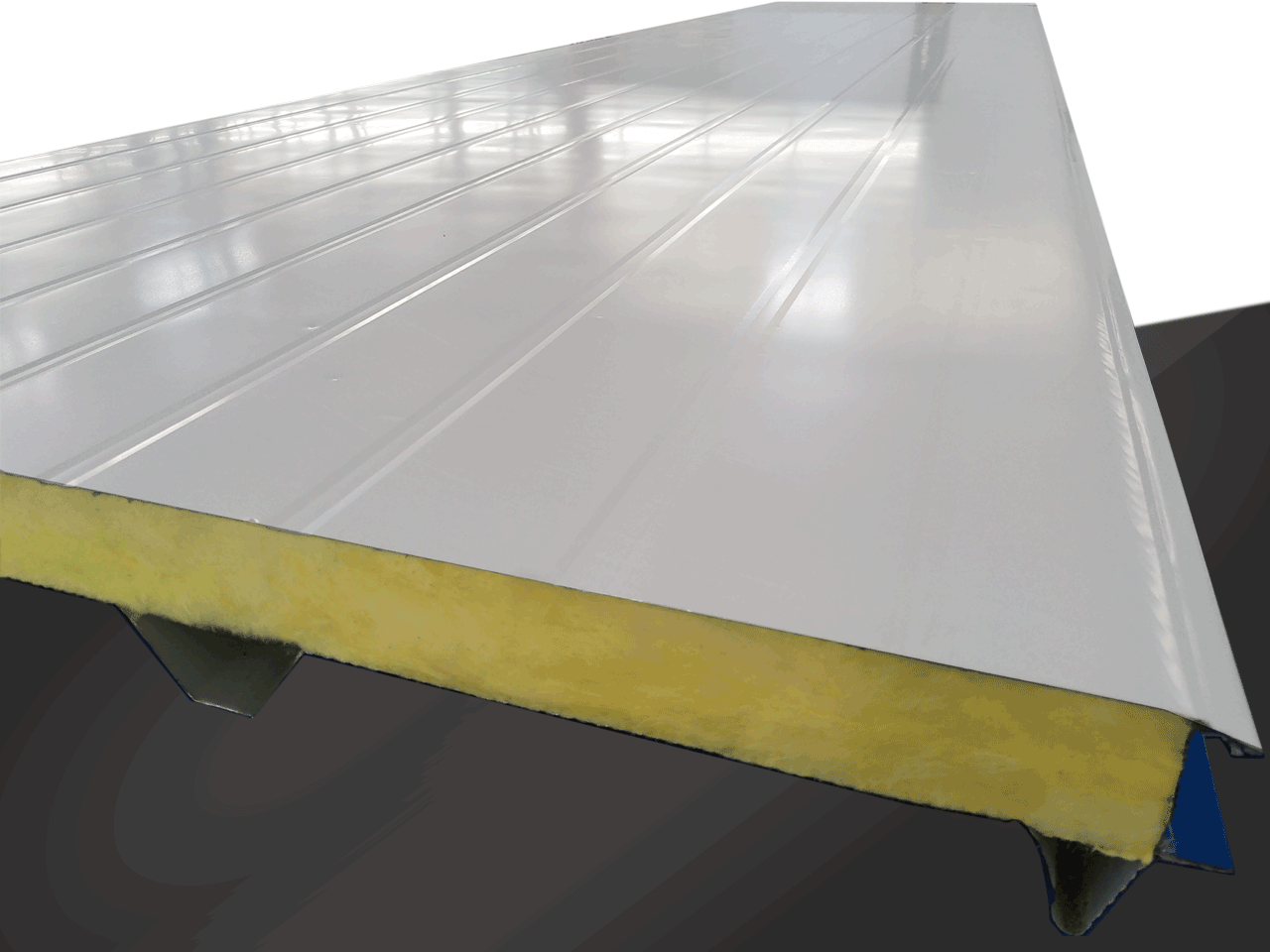

The USP of glasswool sandwich panels is its fire-resistant capability. Glasswool panels are made from non-flammable glass fiber which forms the core inner material. This material has fire prevention capability and excellent insulation properties. Other than that, it also has sound absorbing capabilities, so glass wool finds usage in soundproofing as well. This core material is sandwiched between two layers of metal sheets.

The core layer is made up of fine, long, inorganic fibers that are bonded over high temperature using a binder. These fibers (each of approx. 6 - 7 microns diameter) are spread across to trap millions of minuscule pockets of air in them which in turn creates best-in-class thermal and acoustic insulation. Being lightweight, glass wool panels are also quite easy to transport and install. Other than this, glasswool is natively chemically inert and does not have any impurities like sulphur and chloride. The raw materials which are made from are renewable. It is non-corrosive and does not allow mold to grow.

Glasswool panels are an excellent choice for both wall and roof cladding. Prefab Developer has wide experience in manufacturing insulated sandwich panels of glasswool. These panels are lightweight, have high tensile strength, and come with excellent resilience.

Features of glasswool panels:

Fire safety - Since the inner core material is made from non-flammable glass wool as the insulation material, it prevents fire from spreading. Thus, glasswool panel construction is suitable for fire areas because it does not generate harmful gasses during a fire.

Thermal insulation - The glass fiber used in these panels are as thin as 4 to 6 microns and uniform in composition. It is made from glass sand with high-speed centrifugal force. Glasswool panels, therefore, give best-in-class thermal insulation effect with unique water- repellent treatment.

Sound absorption effect - Glass wool has tiny air pockets that trap air. Sound needs air as a medium of traveling, which is thus restricted by the air pockets.

Anti-corrosive effect - Glass wool is an inorganic product, therefore there is hardly any deformation or corrosion that stays for a long time. Glass wool can retain its original shape and has a really good ability to withstand shocks, pressures, or vibrations.

Properties Insulation – Glasswool

Width - Wall - 1170 mm

Width - Roof - 1000 mm

Core Thickness (mm) - 50 60 80 100

U Value (W/m2 K) - 0.89 0.67 0.43 0.36

R Value (Btu / hr-ft2 - *F) - 14 17 21 27

Facia Options Density (Kg/M3) – PPGS/PPGL

Thermal Conductivity at 50 degrees C Mean Temperature (W/m0K) – 0.033

Compressive Strenght at 5% Deformation (Kg/cm2) – 0.4896

Recovery after compression – 90% min

Service Temperature: -190 to +250 degree C

Water Absorption (Volume %) - Less than 2% in accordance with IS : 3144/BS:3978

Sound Reduction (db) – 28 - 30

Fire class - Non - Combustible

Our EPS Sandwich Panel is used in:

© 2022 Prefab Developers |All Rights Reserved. Powered By VMS Pvt. Ltd.